Amazon has developed a new warehouse robot This uses touch to search around the shelves to find the right product to send customers.

The robot, called Vulcan, is a significant step towards the manufacture of robots less sausages compared to human beings. Maintaining the tactile capacities of robots can allow them to take more execution and manufacturing work in the coming years.

Aaron Parness, director of Amazon robotics, who led the development of Vulcan, explains that touch detection helps the robot to push the elements on a shelf and to identify what it is. “When you try to store (or choose) items in one of these pods, you can't really do this task without getting into contact with the other elements,” he said.

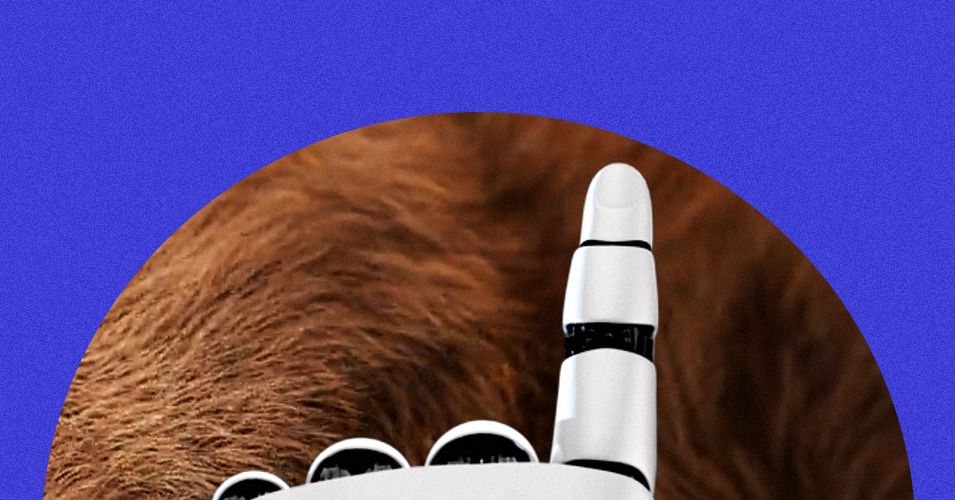

The Vulcan system consists of a conventional robotic arm with an appendix of the personalized spatula type to enter a shelf, and a miller to enter items to remove them.

Vulcan has sensors on several of its joints which allow the robot to detect the edge and the contours of the elements. Parness says that automatic learning is the key to giving meaning to the sensor signals and is also part of the algorithmic loop which controls how a robot takes measures. “The special sauce that we have is the interpretation of the couple's software of the force and the way in which we pack them in our control loop and in our movement plans,” he said.

Amazon revealed Vulcan in an execution center in Hamburg, Germany today. The company claims that the robot is already working in this installation and another in Spokane, Washington.

The new robots will work on the same line as human pickers and will aim to save them from the background of the background by entering more articles from the shelves which are high or low. The elements that the robot decides that it cannot find will be reassigned to human workers.

“Amazon stores many different products in the bins, so searching is necessary to withdraw a specific object to fill an order,” explains Ken Goldberg, robotics at the University of California in Berkeley. “So far, it has been very difficult, so I'm curious to see the new system.”

Goldberg says that research on the detection of robotic touch has progressed in recent years, with many groups working on the detection of joints and the surface. But he added that robots have a long way to go before they can equal the tactile capacities of flesh and blood workers. “The human feeling of touch is extremely sensitive and complex, with a huge dynamic range,” explains Goldberg. “The robots are progressing quickly, but I would be surprised to see human equivalent sensors (skin) over the next five to ten years.”

Robot colleagues

Despite this, Vulcan should help automate more work currently carried out by humans within the vast Empire of Amazon of realization centers. Company has Increased automation In recent years with robots infused by Ai capable of grasping and transporting packaged packages and boxes. The storage and recovery of the articles of the shelves is one of the most difficult jobs to do for robots, and it depends strongly on human work.

Parness says that he does not provide that robots take all the work carried out in Amazon's realization centers. “We don't really believe in 100% automation or the end of the execution,” he said. “We can reach 75% and have robots working alongside our employees, and the sum would be higher (than the only two).”